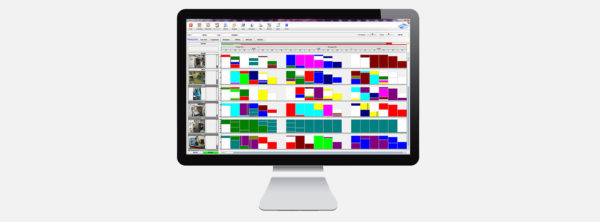

Rayburn has invested in sophisticated production planning software. Fully integrated with our Sage 1000 Enterprise system.

Live shop floor and machine data collection provides a robust real time solution supporting effective and efficient works order processing.

The integration between Sage and Seiki is a vital part in the daily running of Rayburn. Not only does this allow us to track where your job is, it also assists with customer acknowledgments. Our planning system schedules a job from start to finish which shows the planned end date therefore allowing us to give a quick and simple turnaround for acknowledge dates on your order.